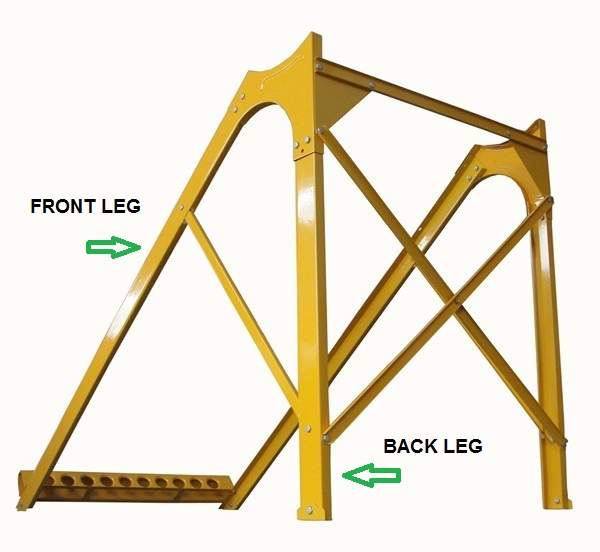

Solar water hater support frame production line-Front & back leg produce

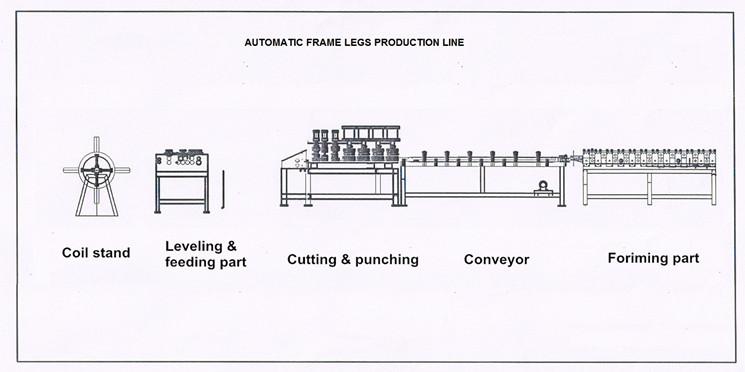

Consist of:

1 set steel roll stand, 1 set hydraulic system, 1 set Cold bending forming machine, 1 set punching & cutting machine, 1 set controller cabinet.

Application:

Solar Water Heater Support Frame front & back leg automatic forming, punching and cutting.

Description:

One time punching holes and forming. Operation only required entry the material to the pipe line. All molding rollers adopt the material of Gr12 high hardness steel. After 810 centigrade high temperature oil quenching heat treatment, ensure the wear resistance of the mold. Greatly improve the service life of molding rollers. Forming width and shape can be customized.

Equip with 4 sets punching molds, 1 set parallel cutting mold, 2 sets left & right diagonal cutting molds. Front & back leg, left & right leg cutting no need mold change, can be auto control.

Parameter data | |||

Power | 4.0KW | ||

| Voltagee | 380V | ||

| 8 hour Max. efficiency | 2500meter forming | ||

| Processing thickness | 1.0~1.5mm | ||

| Weight | 3200KGS | ||

| Floor space (L*W*H) mm | 7500*1200*920mm | ||

| Production material | GI & SS | ||