1. FOAMING LINE PHOTO

2. INTRODUCTION

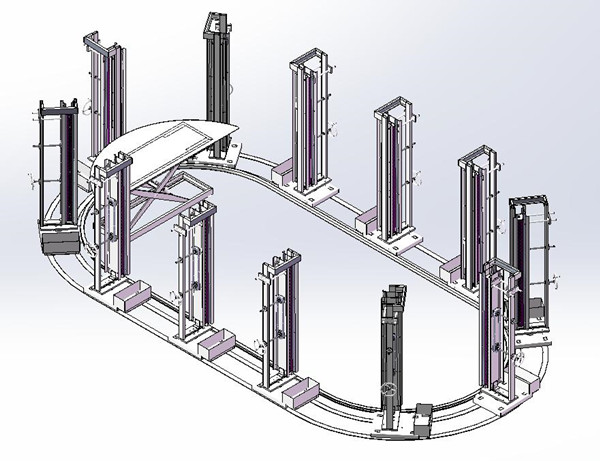

This foaming line include three types main foaming positions

1). Manifold load position, main function fix the well-assembled manifold on the foam stand, install the foaming plugs. Check that the manifold if firmly fixed and the foam plug is in place.

2). Filling foaming agent position, main function is use foaming gun inject the foaming agent into the manifold insulation layer space. After the completion of filling, immediately close the manifold and control the working process of the entire foaming line.

3). Unloading position: this station is to remove the manifold from the foaming stand and recycle the foaming plugs.

Main features: the whole production process adopt the assembly line operation, improved the operation efficiency. The way of fixing the manifold is advanced, the operation is simple and reliable. The foaming plug can recycle in foaming stand side box, convenient in use. This production line separated the original foaming process to few steps, easy for the workers operate. Each station can arrange 1~2 people to operate according to the workload.

3. MAIN STRUCTURE

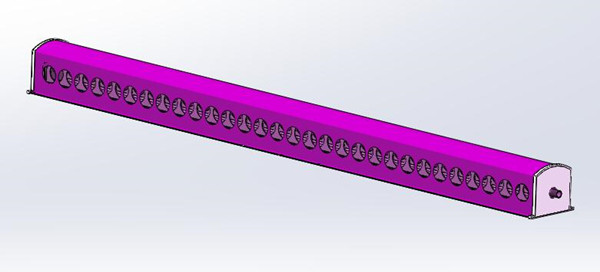

1). Foaming line rail, it is one of the main mechanisms of manifold conveying, consisting of special chain, drive mechanism and special rial. Smooth operation and manual control of starting & stopping position.

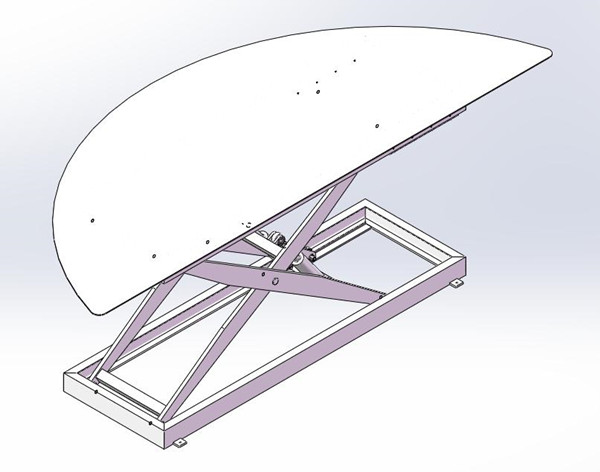

2). Foaming stand component: it is composed of professional car and manifold fixing frame.The fixed frame can rotate at any angle as required.

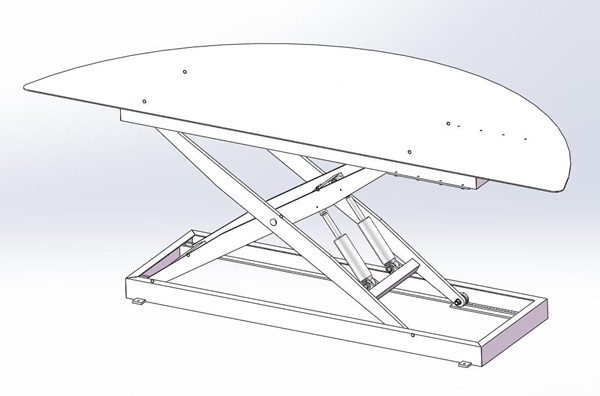

3). Lifting platform: composed of hydraulic system and lifting mechanism, the lifting platform is safe and reliable.

4). Foaming machine: not include in the offer, if need can offer independently.

4. MAIN PARAMETER & MANIFOLD SHAPE

1). Shape: suitable for all kinds of manifold, such as square, circular, etc.

2). Dimensions: normal 25 tubes or 30 tube or less

3). Special specifications or size can customized

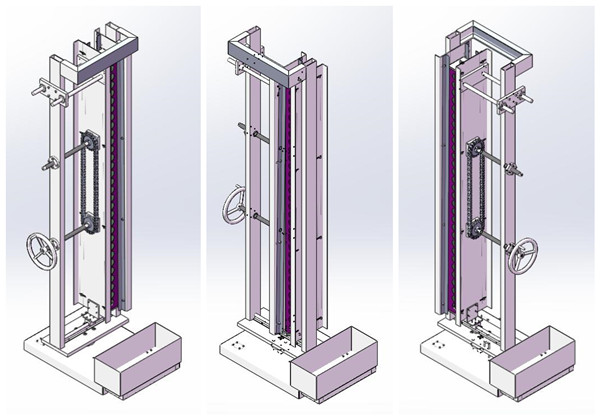

5. FOAMING STAND DIFFEREN POSITION EFFECTS

6. FOAMING STAND INTRODUCTION

Foam frame can rotate 360 degree on the car, in the manifold process of loading and unloading, can choose different location base on operator used to. Manifold compression and separation, only turn the handwheel can be realized easily, avoid before multipoint clamping trouble. Guide with a standard guide rail and linear bearings, precision is more accurate and reliable. Produce different size manifold, adjusting 40X40 Angle steel respectively can be realized, operation is very convenient.

Each foaming stand is equipped with a box, for easy use and recycle foaming plug.

When finish loading of the manifold, the bolt is fixed to the hole of the car, this way can fix the foaming stand in one direction, which is convenient for the operation of the foaming agent position. Unplug the pin when unloading, the operator according to their own needs to select the appropriate location operation.

7. FOAMING AGENT INJECTION OPERTION PLATFORM

This platform is controlled by hydraulic system, the platform adopt the antiskid riffled steel plate, good stability, safe and reliable. The operation of the foaming line control is settings on the platform, easy to operation and control. The lowest point is convenient for personnel to go up and down, and the highest point is convenient for foaming operate.

Foaming line exclude foaming machine and foaming plug.