1. OUTER MANIFOLD AUTOMATIC FORMING MACHINE

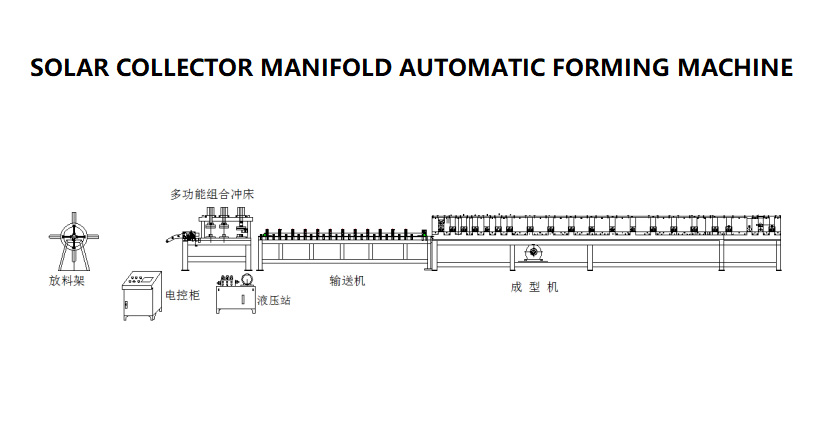

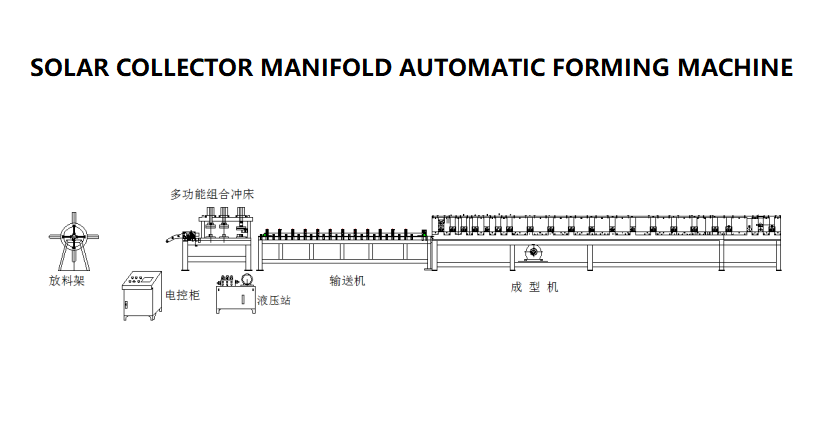

This production line consists of 4 parts:

1. Automatic discharge system

2. Automatic punching and cutting system

3. Steel plate conveyor

4. Outer manifold forming machine

A. Automatic discharge system

The discharge system is driven by a 3KW electromagnetic brake motor to rotate the material rack. The rotation time is controlled by PLC, which ensure discharge material accurately and steadily. Load the steel roll on the material rack with the forklift or line crane, manually tighten the material shaft. To prevent the material sliding out of the frame during rotation, lock the material baffle bar on the support frame, material rack bear the weight of 3Ton.

B. Automatic punching and cutting system

Automatic punching & cutting part is actually a multi-function hydraulic combination punch machine. Working principle is work is driven by cylinder, mould complete the specified action on the mould table. and mould table can install 2 sets molds, one punching, one cutting.This system is equipped with an automatic console, which can control all actions through PLC. Users can set the specification size through the touch screen as required.

The mould is made of CR12 molybdenum vanadium, high performance mould steel with vacuum treatment, through rough processing, heat treatment, precision machining, precise assembly and other processes, it is durable.

C. Steel plate conveyor

The main body of plate conveyor adopts pine board, which can protect the finished products of stainless steel, galvanized steel, color steel plate and other materials from scratches. In the same time, ensure the conveying plane is relatively smooth. Pressure wheel is a passive rubber wheel, ensure a good delivery effect and avoid damage product, which also not easy to slip.The positioning wheel is installed at a certain distance between the two sides of the conveyor, effectively ensuring the product to enter the molding machine accurately. The transmission system of the conveyor is connected with the forming machine, which drives the conveyor through the forming machine, ensuring the synchronous operation of the equipment..

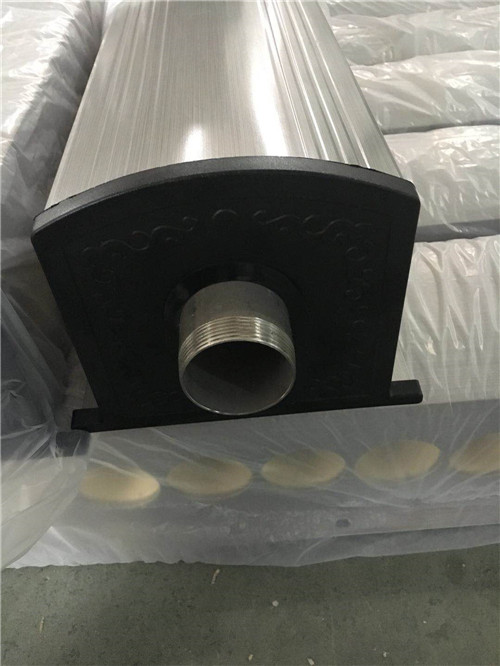

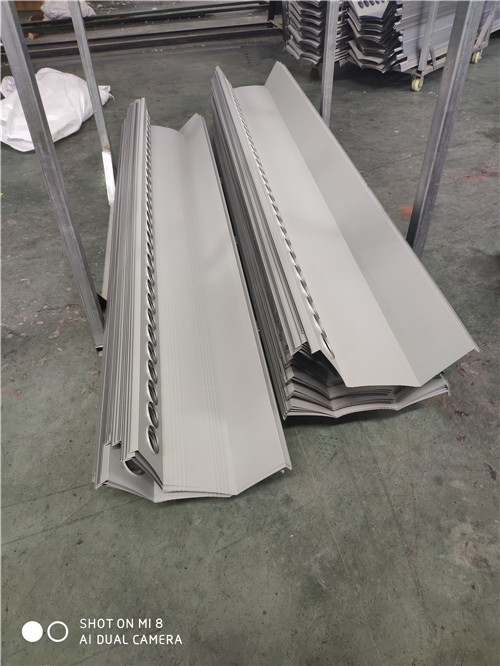

D. Outer manifold forming machine

Outer manifold forming machine up and down rollers total 20 sets, roller materials using 40 CR, conditioning treatment after rough machining - heat treatment - fine finishing process. This material will not damage the color plate, galvanized sheet, etc surface protective film, make sure the product not easy to rust. The wheels are durable and not easy to wear.

The machine is driven by a 3kw speed regulating motor. The speed can be adjusted to synchronize with the punch & cutting machine, ensure the machine can give full play to the maximum working efficiency. Daily output 200PCS outer manifold per 8 hours.

The total length of this production line is 24 meters (including the length required for outputting the goods), 2 meters wide and weight 7 tons.