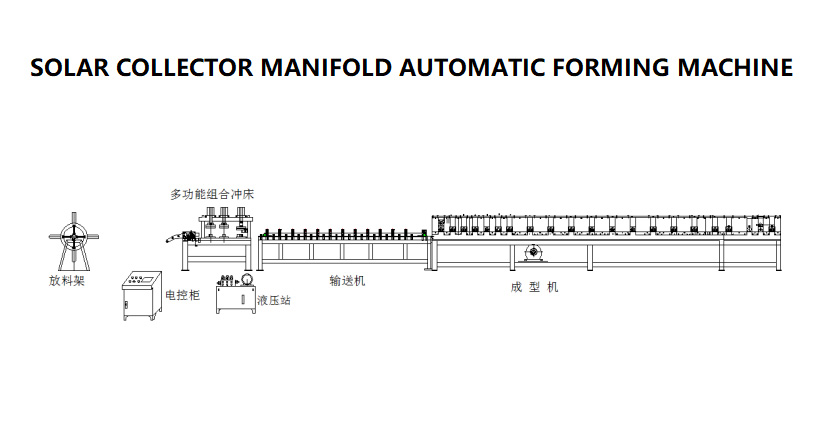

1. INNER MANIFOLD AUTOMATIC FORMING & WELDING MACHINE

A. AUTO STEEL COIL LOAD SYSTEM

The auto steel coil stand system is driven by a 3KW electromagnetic brake motor to rotate the material rack, the rotation time is controlled by PLC, which can accurately and steadily load the material. Load the steel roll on the coil stand with the forklift or line crane, and manually tighten the material shaft, in order to prevent the material sliding out of the coil stand during rotation, lock the material baffle bar on the support frame. Coil stand can bear the weight Max. 3TON.

B. AUTO PUNCHING PARTS

Equip Molds:

1 set 58mm inner manifold punching mold - double hole

1 set 58mm inner manifold flanging mold - double hole

1 set 47mm inner manifold punching mold - double hole

1 set 47mm inner manifold flanging mold - double hole

1 set cutting mold

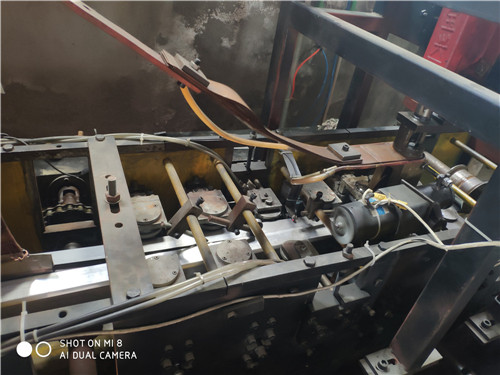

Automatic punching parts is a multi-function hydraulic combination punch machine, principle of work is driven by cylinder, mould complete the specified action on the mould table. Mould table can be placed on many molds. Include punching mold, flanging mold, cutting mold. The system is equipped with an automatic console, which can control all actions through PLC. Users can set the specification size through the touch screen.The set parameters include hole number, holes centre distance and hole distance from edge.

The mould is made of CR12 molybdenum vanadium, high performance mould steel with vacuum treatment, through rough processing, heat treatment, precision machining, precise assembly and other processes, durable in use.

The mould is fixed on the platform of the hydraulic press by four bolts. There are long grooves on the mould, when adjusting the equipment, adjust the punch position by adjusting the shifting mould. There is a mould backer on the mould table, easy to adjust.

C. FORMING MACHINE

Inner manifold forming machine rollers up and down total 18 sets, roller material using 40 cr, through conditioning treatment - rough machining - heat treatment - fine finishing process. This material will not damage the surface of thin steel sheet, ensure product will not easy to rust.This material wheels are durable and not easy to wear.

Forming machine driven by 3 kw speed motor, speed can be adjusted to synchronize with punching & shears, ensure highest efficiency of the machine working. Motor adopts CVT, linear velocity at between 0.5 m/min - 5 m/min can be adjusted, after statistics, the production efficiency is 200PCS per 8 hours for normal work.

The total length of this production line is 25 meters (including the length required when the inner manifold output), width 2 meters.

D. WELDING PART

The welding of the product is completed by high frequency welder. Welding current frequency and other parameters are controlled by independent controller. Because the inner manifold is continuous welding, welding machine frequency need increased, appropriate welding power is 100 kva. Current adjusted base on the thickness of the material, adjusting range 50A, linear velocity in 1 m/min - 1.5 m/min. The speed of the welding head is fixed, equipment forward speed is adjust according to the speed of the welding head, until the desired weld. The high frequency welding system adopts Baoxing, which is an old brand that has been tested by the market for decades. The welding performance is stable and reliable.

E. CUTTING PART

Cutting part adopts high speed steel saw blade, when welding product output, forward movement meet of the baffle, positioning mould fix product through the cylinder, then cutting head slowly downwards movement to cut off the products. Cutting speed can be adjusted by frequency converter. In the process of cutting, forming machine and welding machine no stop working. After cutting a product, cutting positioning device automatically return, waiting for the next product. Whole process efficient and accurate, greatly enhance production volume.

F. PARTS LIST

1. PLC brand Dongyuan of Taiwan

2. Touch screen is made of Willon

3. The servo system is Dongyuan of Taiwan

4. The limit switch is Schneider

5. The electrical component is Zhengtai

Automatic feed unit is 5 points, 5 points with the mould is 58 inner manifold punching mold - double hole, 58mm inner manifold flanging mold - double hole, 47mm inner manifold punching mold - double hole, 47mm inner manifold flanging mold - double hole and cutting mold