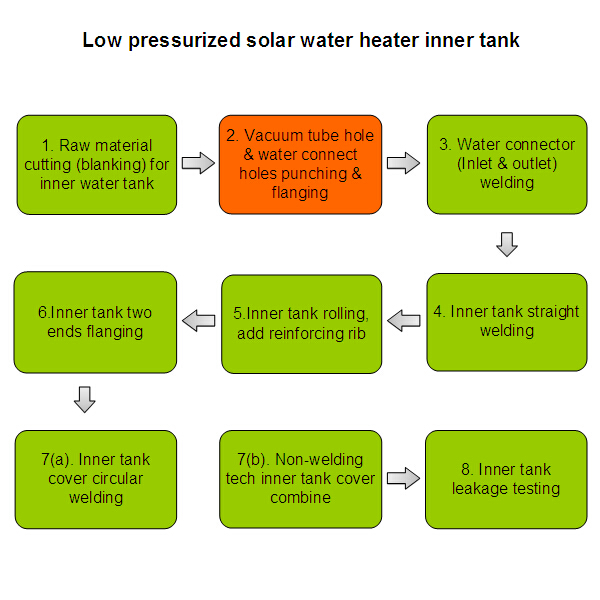

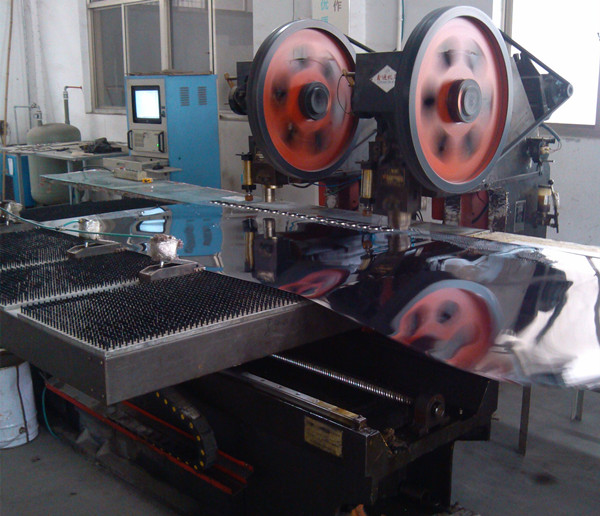

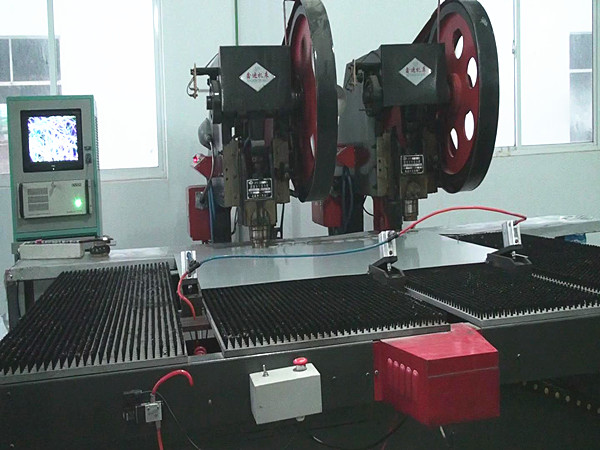

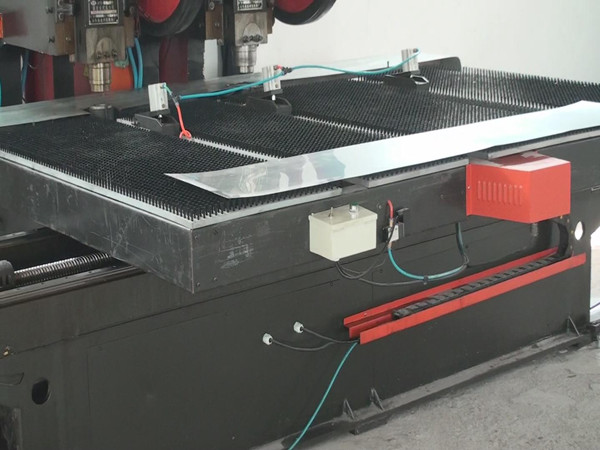

Solar collector manifold production line-Step 2. Vacuum tube hole punching & flanging

Application:

Solar collector Inner and Outer manifold plate automatic Punching and Flanging

Deployment Component:

1. T16 deep throat punching machine - 2 units,

2. Automatic feeder – 1 unit,

This machine belongs to modular automatic punching production lines, can be inner and outer tank automatic punching. Control software adopt the PT - 2002 CNC dedicated system, man-machine interface system. Install twice positioning system. Servo system adopts Japanese YASKAWA, electrical element use Markus Schneider, cylinder adopt Taiwan AirTAC.

Parameter data | |

Mould Digits | 2 positions |

Position Accuracy | ±0.10mm |

Max. Processing Sheet Width | 1250mm |

Max. Processing Sheet Length | 2500mm (30 tube 58mm diameter) |

Max thickness | 58mm dia 0.5mm / 47mm dia 0.5mm / 70mm dia 0.4mm |

PN | 160KN |

Air Pressure | 0.5Mpa—0.8 Mpa |

Power | 6KW |

Voltage | 380V 50HZ |

Labor | 1 person |

8 hours Max. Efficiency | Punch 12000 holes |

Weight | 6000kg |

Size (L*w mm) | 2500*4000 |

Drawing input format | DXF format or Program |

YOUTUBE LINK: https://www.youtube.com/c/EricZhuSolar