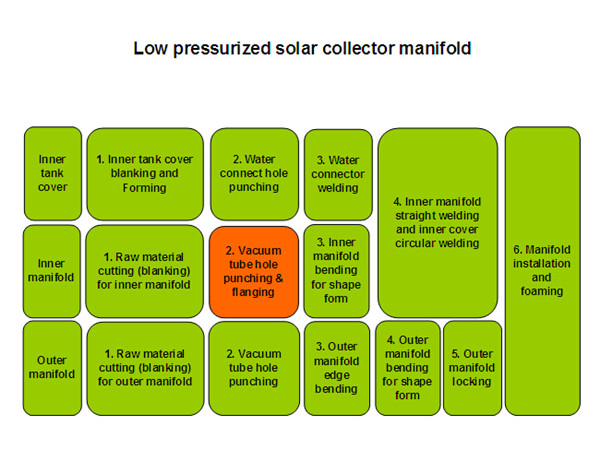

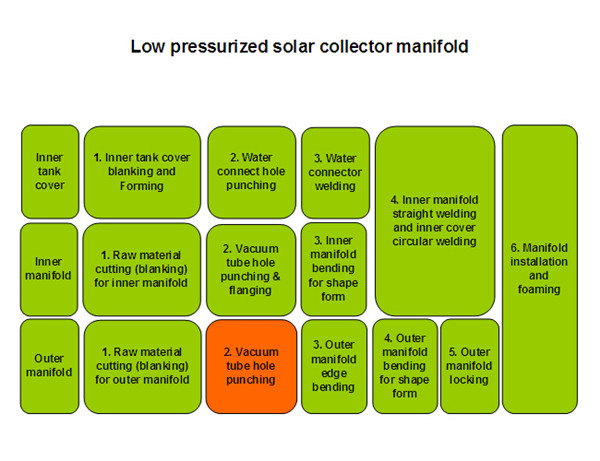

Low pressurized solar collector manifold production line Step 1.Raw material cutting (blanking) for inner & outer manifold

Application:

Solar collector Inner manifold Punching and Flanging.

According to the Solar Water Heater product’s plate characters, increase the depth of the holes throat, provide more space to working. Adopt the crankshaft horizontal structure, rigid and rotating key clutch. Machine body made of precision cast iron

Parameter data | |

Nominal Pressure (PN) | 160KN |

Slide Stroke | 60mm |

Slide adjustment | 40mm, |

Distance of body and the slide center | 500mm |

Shut Height | 170mm |

8 hours Max. Efficiency | 2000 holes |

Max. processing material thickness | 58mm- 0.5mm 47mm- 0.5mm 70mm -0.4mm |

Voltage | 380v 50HZ |

Power | 1.5KW |

Operation Labor members | 1 person |

Weight | 1100kg |

Floor space (L*W*H) mm | 1100*600*1700 |