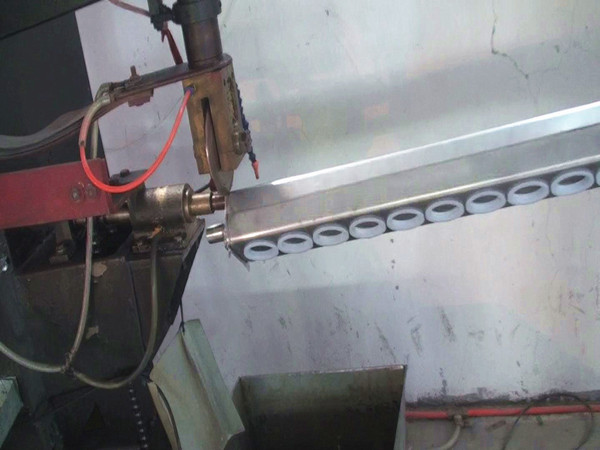

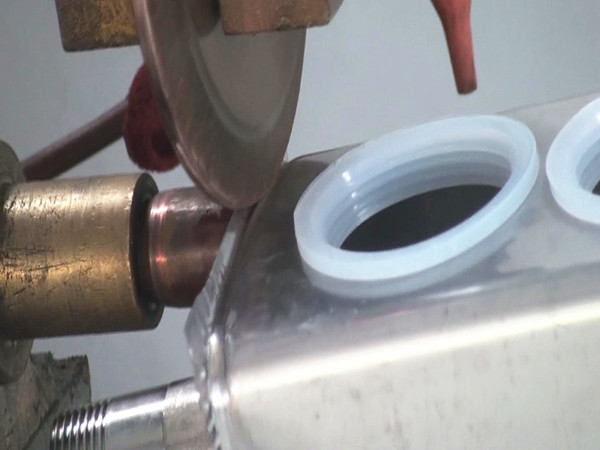

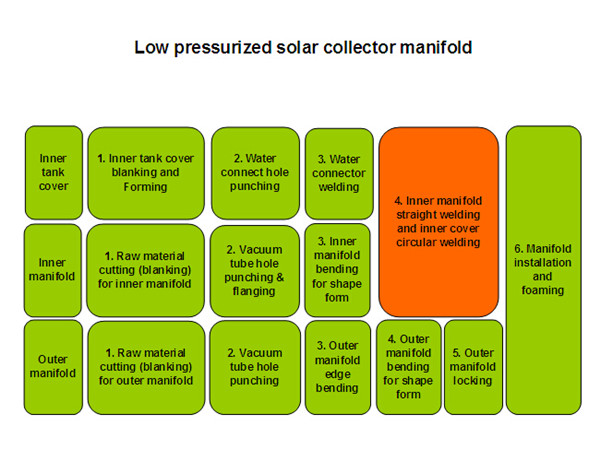

Low pressurized solar collector manifold production line Step 4. Inner manifold straight welding and inner cover circular welding

Application:

All-automatic Punching and Flanging for inner and outer tank steel plate

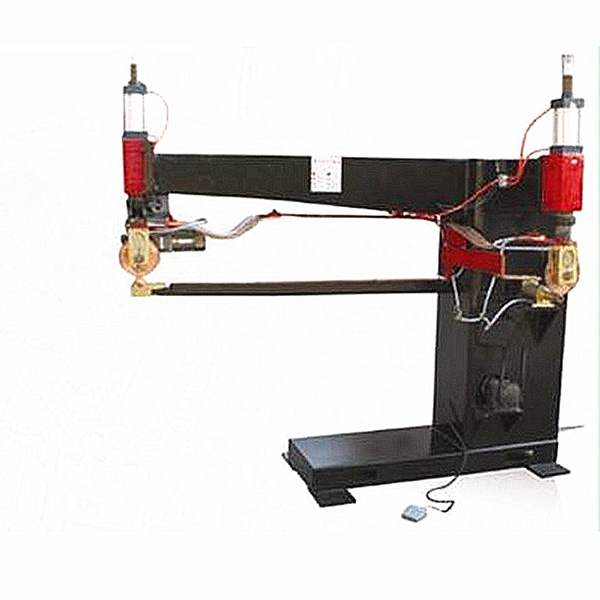

Special for solar products and stainless steel material circle and straight seam welding, heavy-duty machine body. Circuit adopts high power module and the microcomputer control system, current stability, easy to adjust. Main transformer uses imported silicon steel sheet, all copper sand covered wire primary winding and secondary, water cooling protection way. Welding copper wheel are high temperature resistant chromium zirconium copper, use gear motor, copper turbine drive.

Parameter data | |

Maximum welding Plate thickness | 0.35mm+0.35mm 0.5mm+0.5mm |

Max Welding Length (two times) | 2600mm |

Welding arm length | 1300mm |

Main Transformer Power | 50KVA/ 100KVA |

Rated Capacity | 50KVA/ 100KVA |

Voltage | 380v 50HZ |

Secondary maximum short-circuit current | 20KVA |

Duty cycle | 20% |

Air Pressure | 0.5Mpa |

Operation Labor members | 1 person |

Weight | 400kg |

Floor space (L*W*H) mm | 2450*500*1850 |