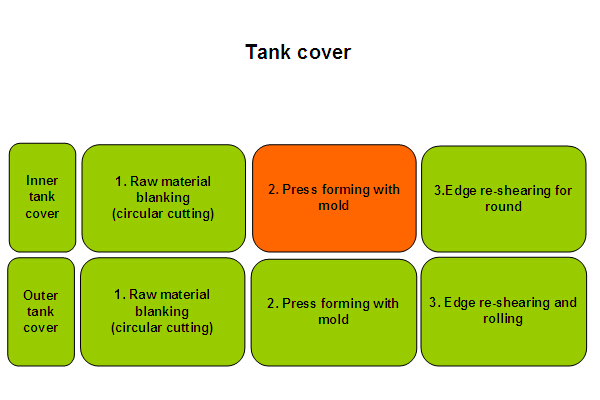

Pressurized Inner Tank Cover & Outer Cover Step 2. Press forming with mold

Application:

Pressurized Inner tank cover and outer cover forming machine, need mold cooperatively

Three girder is made of high quality of Q235 steel weldments, four-post type structure, good rigidity, partial load resistance is strong.Weldments with tempering treatment, eliminate the internal stress, prevent deformation and improve the welding performance, columns, the piston rod 45 #, intermediate frequency quenching, hard chrome plated surface treatment, 45 # oil cylinder forgings, the strong surface after rolling process in cylinder roller, make the hydraulic oil cylinder has sufficient strength and stiffness and smoothness;Main oil cylinder seal USES the domestic famous brand seals, ensure reliable sealing performance, prolong service life.

Parameter data | |

Nominal pressure PN | 4000KN |

Return force PN | 500 KN |

Working table size(L*W mm) | 12600*1200mm |

Max. Top output PN | 1600KN |

Max working pressure | 25MPA |

Max. Slide stroke | 800mm |

The Max. ejector stroke | 300mm |

The slider work surface maximum distance | 1250mm |

Voltage | 380v 50HZ |

Power | 22KW |

Operation Labor | 1people |

Suit to cover Diameter | Max. 800mm |

Weight | 15000kg |

Size (L*W*H) mm (machine & hydraulic system) | 1250*1870*3850 & 1250*1400*1600 |