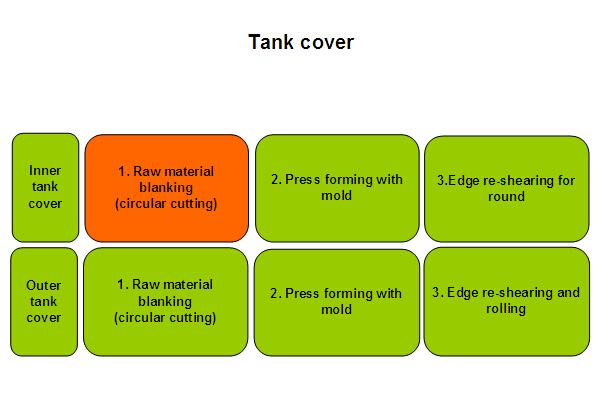

Pressurized Inner Tank Cover Step 1. Raw material blanking (circular cutting)

Application:

For pressurized inner tank cover raw material blanking - round cutting

Raw material must be suitable size square steel sheet, so need use cutting machine to cut the square piece in first.

Cut round blade made of Gr12 high hardness steel and high temperature oil quenching heat treatment after 810 degrees, to ensure its die hard grind, Can cut circle diameter 360 mm - 800 mm can be adjusted, and between efficacy than ordinary mechanical 3-5 times.

Parameter data | |

Cutting Diameter | 360~800mm (base on mold for exact cutting size) |

Max. cutting Thickness | 1.0~1.8mm stainless steel |

Power | 1.5kw |

Voltage | 380v 501hz |

Air Pressure | 0.5Mpa |

Operation Labor | 1people |

Weight | 700kg |

Size (L*W*H) mm | 800*650*1350 |

Before round cutting, need cutting raw material to square piece in this machine