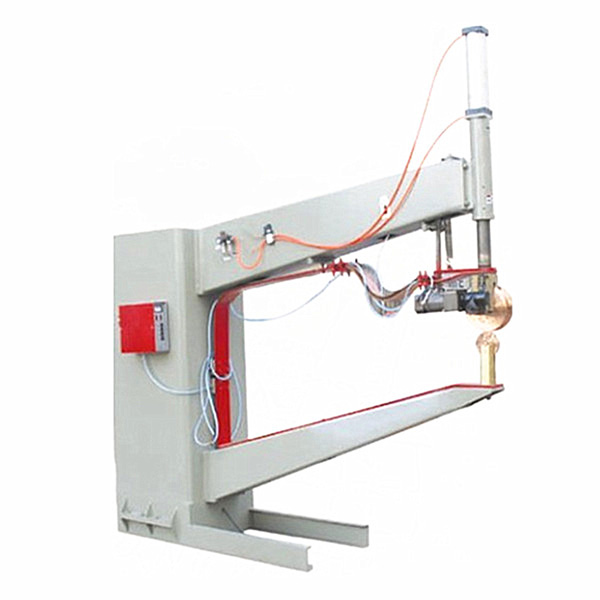

Solar Water Heater Water Tower machinery

Application:

Use for water tower tank straight welding and tank cover circle welding

FN180kv AC pulse welding seam for water tower adopt high-power module and microcomputer control system, urrent stable and easy to adjust. Main transformer use imported silicon steel, copper sand envelope of the primary winding and a secondary copper. Main circuit useg high-power thyristor, the current output is stable. Conductive paths use full water cooling protection to prevent circuit aging caused by high temperature. Welding copper wheel use chromium zirconium copper with high thermostability and wear resistant to prevent excessive wear of the welding wheel. Double welding wheel can do straight seam and circumferential welding flat bottomed and pointed base welding.

Parameter data | |

Maximum welding thickness | 1.2mm+1.2mm |

Max. effective welding Length | 1800mm |

Main transformer Rated capacity | 180KVA(AC) |

Voltage | 380v 50HZ |

The secondary maximum short-circuit current | 40KA |

Duty Cycle | 50% |

Air source (air pressure) | 0.5Mpa—0.8 Mpa |

Operation people | 1-2 people |

8 Hours Max. Production Volume | 150 pcs water tank |

Weight | 1600kg |

Size (L*W*H) (mm) | 2750*750*2600 |