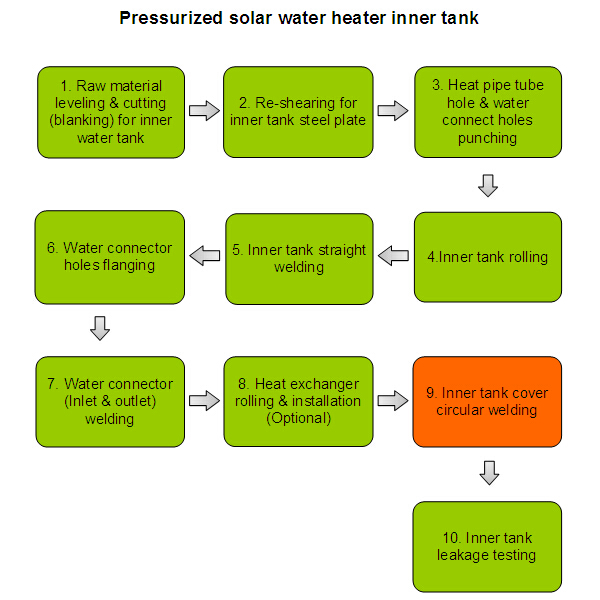

Pressurized solar water heater inner tank production line Step 9. Inner tank cover circular welding

Application:

Pressurized inner tank cover welding.

Machine adopt gantry frame welded structure, good rigidity. CNC wire welding equipment are installed with high precision linear guide, maintain the equipment before and after the parallel vertical degree. Frequency converter, motor speed precision rack driving, with electromagnetic clutch. Welding torch USES of miniature cylinder lifting to multi-faceted adjustment. Automatic welding, can also be manually repair welding, weld is bright and clean. One-side welding, double side protection forming. After welding deformation is small, no intergranular corrosion. Wire feeding pattern in argon arc welding machine adopts Japan panasonic.

Parameter data | |

Maximum welding thickness | 1.5mm stainless steel – KR-350/ 3.0mm galvanized steel – GL3-350 |

Max. Effective Length | 2500mm |

Welding Diameter | Φ385mm ( 1 set mold only) |

Air Pressure | 0.5Mpa—0.8 Mpa |

Voltage | 380v 50HZ |

Power | 6.0KW |

Operation labor | 1-2 person |

8 hours Max. Efficiency | 80pcs inner tank |

Weight | 4500kg |

Dimension (mm) (L*W*H) | 3700*700*1800 |

YOUTUBE LINK: https://youtu.be/sGAmauAtNs8