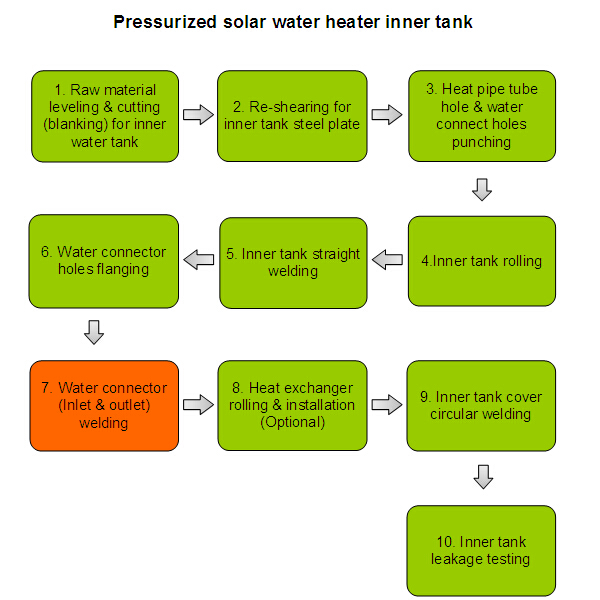

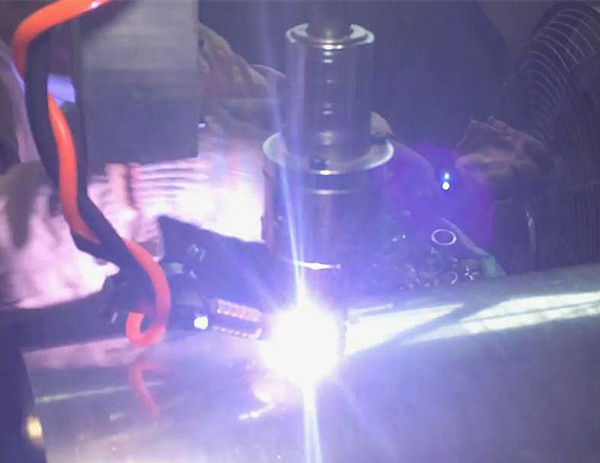

Pressurized solar water heater inner tank production line Step 7. Water connector (Inlet & outlet) welding

Application:

Inner water tank water connector welding

Using the microcontroller circuit, anti-interference ability ,count correctly, the use of the Mitsubishi inverter debugger can be with Welding speed, welding speed is uniform. Carbon brush rotating conductive, inert gas welding, which can effectively prevent the material to intergranular corrosion can choose manual welding and automatic welding. Taiwan AirTAC Cylinder.

Parameter data | |

Nut size | G1/2— G1-1/2 |

Max Plate Thickness (mm) | 2.0mm SS |

Max Output Power | 12 KW |

Equipment Power | 0.1 KW |

Argon Arc Welding Voltage | 380V |

Equipment Voltage | 220V 50HZ |

Air Pressure | 0.5Mpa - 0.8 Mpa |

Operation Labor members | 1 person |

8 hours Max. Efficiency | 200 PCS Nuts |

Weight | 400 kg |

Floor space (L*W*H) mm | 2100*550*1950 |

YOUTUBE LINK: https://youtu.be/3KhNr8Vwn08