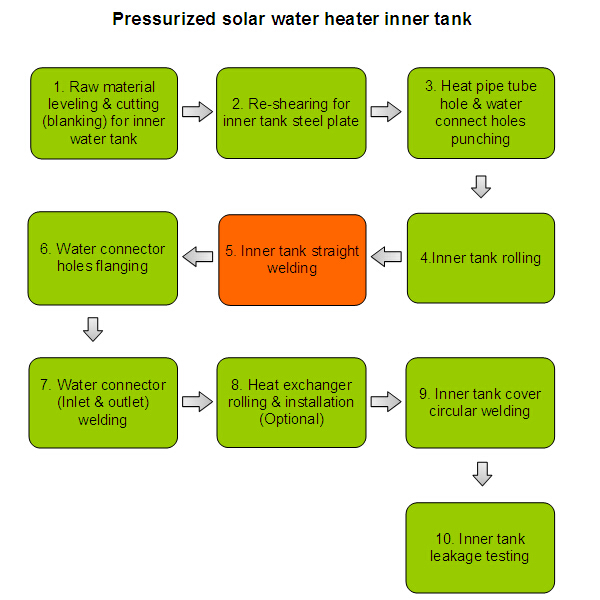

Pressurized solar water heater inner tank production line Step 5. Inner tank straight welding

Application:

Pressurized water tank straight welding.

Machine adopts open welding structure, good rigidity, take water tank conveniently. Clamp using keys type, air add pressure, linear guide, frequency converter, motor speed precision rack driving, with electromagnetic clutch. Welding gun uses miniature cylinder lifting, multi-faceted adjustment. Automatic welding, also can be manually repair welding, weld is bright and clean. One-side welding, double side protection forming. After welding deformation is small, no intergranular corrosion. Argon arc welding machine adopts Japan Panasonic brand machine.

Parameter data | |

Maximum welding thickness | 2.0mm stainless steel – KR-350/3.0mm galvanized steel – GL3-350 |

Max. Effective Length | 2500mm |

Air Pressure | 0.5Mpa—0.8 Mpa |

Voltage | 380v 50HZ |

Power | 6.0KW |

Operation labors | 1~2 people |

8 hours Max. Efficiency | 80pcs inner tank |

Weight | 4500kg |

Dimension (mm) (L*W*H) | 3700*700*1800 |

YOUTUBE LINK: https://youtu.be/rqC0P3JumU8