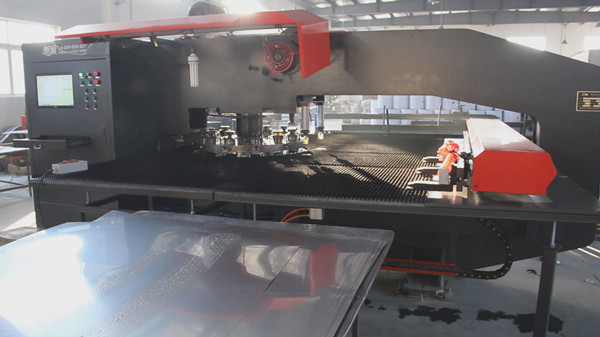

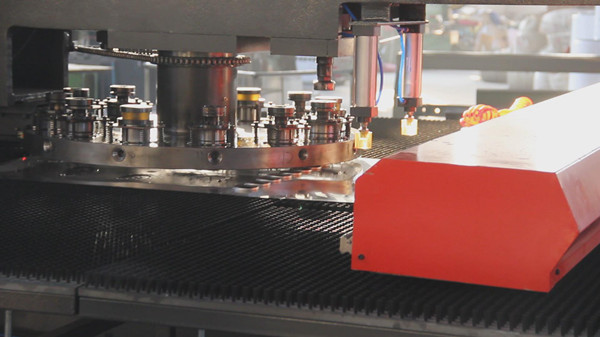

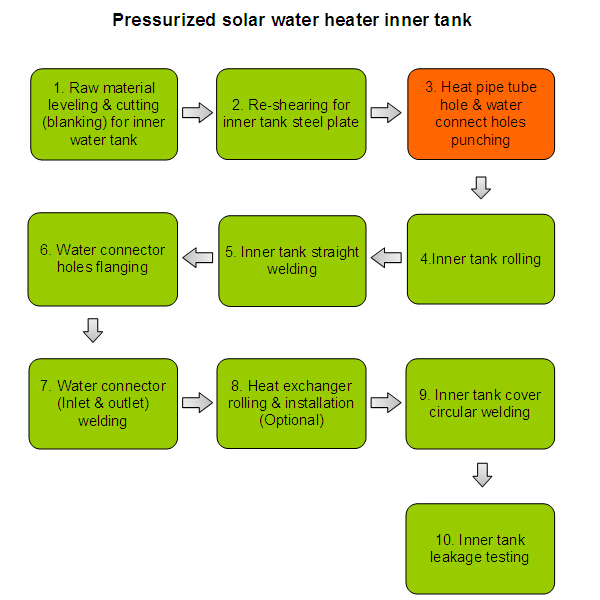

Pressurized solar water heater inner tank production line Step 3. Heat pipe tube hole & water connect holes punching

Application:

All-automatic Punching and Flanging for solar water heater inner & outer steel plate.

This machine is a mechanical and electrical integration, automatic punching press machine, with automatic load materials and cutting system. The body is made of high strength, high-rigidity, welded steel plate, internationally accepted structure bed. The mold plate inlaid oriented high-quality die sets, equipped with 12 sets of mold international universal long orientation, fast loading type mold installation method, CNC machine control system, Japan Yaskawa servo system, Schneider electrical components , Taiwan AirTAC cylinder, precision ball screw and linear guide.

Parameter data | |

Mould Digits | 12 sets |

Position Accuracy | ±0.10mm |

Max. Processing Width | 8 sets |

Max. Processing Length | ±0.10mm |

Max. Processing material thickness | 1250mm |

PN | Unlimited |

Air Pressure | 2.0mm |

Operation Labor | 400KN |

Power | 0.5Mpa - 0.8 Mpa |

Voltage | 1 people |

Weight | 12KW |

Size (L*w) mm | 380V 50HZ |

Drawing input format | 11000kg |