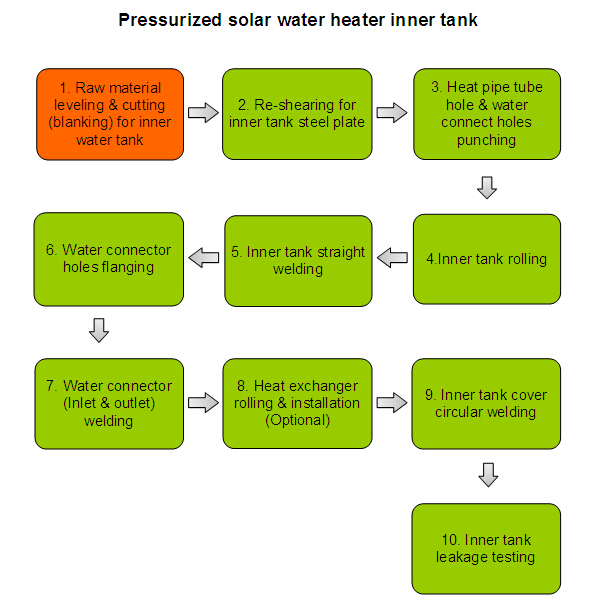

Pressurized solar water heater inner tank production line Step1. Raw material leveling & cutting (blanking) for inner water tank

Application:

Used to pressurized solar water heater inner tank raw material leveling and blanking.

Components:

1). 4 position coil stand with 2 coil holder- 1 set

2). Tractor - 1 set

3). Guardrail buffer pit- 1 pair

4). Cutting machine (Rectifying, counting, scale, cutting function)– 1 set

5). Conveyor – 1 set

6). Pile system- 1 set

7). Control box – 1 set

Total 7 parts

PLC automatic program control, include steel plate feeding, leveling, laminating, rectifying and scale destiny, shearing, transportation, pile plate functions. Input demand shearing size and number, it can full automatic working.

In order to ensure the plate shearing precision, shear feeding spindle power adopt servo motor control. Main shaft made of 45 # seamless steel tube and after quenched and tempered and surface hard chromium plating and fine grinding processing, guarantee the abrasion resistance and smoothness of feeding shaft. Protect plate in the process of feeding from the scratch, tractor roller, two group of outside packages have wear-resisting, oil resistant silicone rubber roller, four groups of leveling roller surface has a single 0.2 mm hard chromium plating. Plate shears blade made of high speed steel is W18Cr4V ensures the service life of blade and shear of the finish. Control system for the machine single control, normal production for unmanned automatic control. To guard against equipment in there is an error in the process of automatic cutting, production line equipped with 4 or more abrupt stop device and automatic error alarm device.PLC, touch screen, servo motor, frequency converter used in Taiwan brand, electrical components adopt schneider or omron, pneumatic components adopt pneumatic southeast of Sino-British joint venture .

Parameter data | |

Length accuracy tolerance | ≦0.20mm |

diagonal accuracy tolerance | ≦0.30mm |

Max. Cutting width | 1300mm |

Max. Cutting thickness | 1.2mm stainless steel |

Nominal pressure | 250KN, |

Air (air pressure) | 0.5-0.8Mpa |

Power (total) | 16kw |

Once the power supply | 380V±10% |

Input circuit voltage | 380V |

Main motor circuit voltage | 380V、 |

Control voltage | 24V |

Frequency | 50HZ |

Operation person | 1 people |