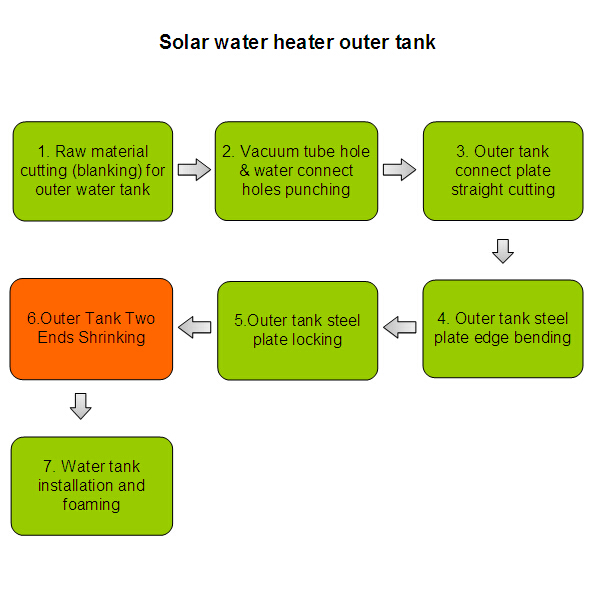

Solar water heater outer tank Step 6.Outer Tank Two Ends Shrinking

Application:

Solar Water Heater outer tank two end automatic shrinking

Production line components

1. 10 meters power transmission - 2 lines,

2. Work piece automatic up and down system - 1 set,

3. Full automatic shrinking machine – 1 set

4. Integrated control cabinet – 1 set

You only need to enter the size of the water tank diameter on the touch screen, the device can automatically operation.

The power transmission line frame is made of high quality galvanized sheet, which is made by bending and splicing. conveying plate adopts high-quality galvanized sheet bending, to prevent scratches on the surface of the tank in the conveying process .each panel is installed silicone rubber. Transmission power using 2 variable frequency motor driving thickening industrial chain to carry on the work piece’s delivery. the speed of delivery can be adjust according to the actual needs of conveying speed at any time. In order to prevent the wearing of the chain, there is a 8mm thickness nylon plate under the bottom of the chain.

The workpiece automatic up and down system uses frame structure, installed with lots automatic induction system. Two sets of automatic suckers : grap the workpiece from upper feeding line to shrinking machine, and take the finished workpiece form Shrinking machine to Conveying line. There is a Electric cylinder of Japanese SMC on the sucker. According to the size of the tank diameter, this machine can automatically control the height of the sucker.

The machine body is made of steel weld steel plate .in order to prevent the deformation of the body, this machine body adopt vibration aging treatment. Body is horizontal structure. To ensure concentricity of front and back shrinking equipment, bottom have TCA35 linear guide. Front and back shrink device mounted with two servo motor, Transmission of upper and lower retraction wheel through hold-in range line to avoid deviation. the device install a servo motor to rive the ball screw to adjust the length of the water tank automatically. In order to prevent the dust into the body affect the life of the ball screw, the body installed on the organ telescopic dust cover.

To prevent error during production, this production install over six emergency stop devices and automatic alarm device.

Machine control system is a single tone control, normal production is unmanned automatic control.PLC、Touch screen, servo motor, inverter motor is Taiwan Delta. Vacuum sucker, electric cylinder is Japan SNC. Electrical components is Omron or Schneider,Pneumatic Components is Southeast pneumatic.

Parameter data | |

Work piece shrink shape | Teeth with ribs |

| Process diameter | φ450mm—φ650mm |

| Max processing length | 3000mm |

| Processing thickness | 0.3mm-0.6mm |

| air pressure | 0.5-0.8mpa |

| Power | 10KW |

| Disposable Power | 80V±10% |

| Input circuit | 380V |

| The main motor circuit | 380V |

| Control loop | 24V |

| frequency | 50HZ |

| Operation labor | automatic |

| Work piece supply | automatic |

| Line Speed | 2piece/min |

| Weight | 13500kg |

| Size (L*W*H) mm | 15000*2500*2300 |