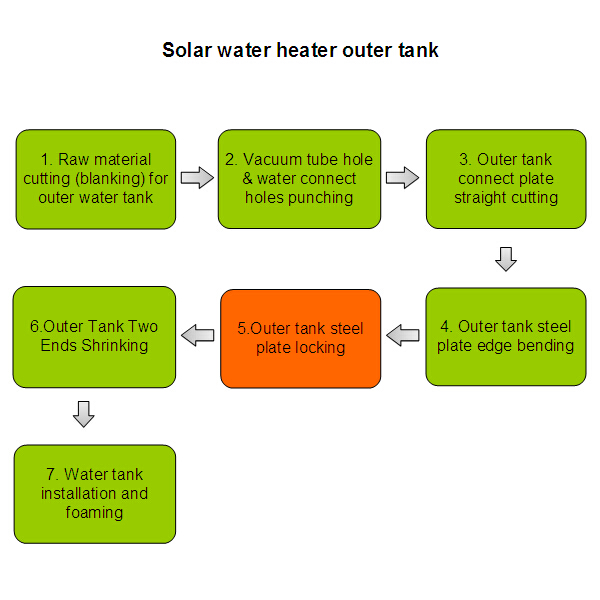

Solar water heater outer tank Step 5. Outer tank steel plate locking

Application:

Solar Water Heater out tank connect edge bending and locking

Production line components:

1. Hydraulic system 1 set,

2. Main computer 1 set,

3. Control cabinet 1 set

Reference 56F/ pressure machine and advanced technical abroad, This machine combine tenon bending and pressing. This machine has high safety, high efficiency, and synthetic appearance after bending.

To prevent the laminated sheet is not strong, there is 800KN hydraulic power system In order to improve production efficiency, this machine specifically install an accumulator to speed up the under pressure and return speed.

The folding mold is made of 6GrW2Si material, can be used more than 500,000times.Modle is tenon and pressure modle.

Mold support beam using φ290mm45 # carbon steel, and after quenching, to ensure the value of the support beam. the support beam fixed at one end, and the other end using the activity support regularly targeted support and openness. Under pressure device is square slide rails with gib. It is easy to adjust the slider gap.

Lubrication system is centralized lubricating oil installations and oil cup quantitative timed lubrication.

Control system is commissioning a single control, two or four joint control during normal production and automatic control

Motor protection: thermal relay, overload protection, ground protection.

To ensure worker’s safety during operation, this machine install light curtain sensor system in both two end of lower pressure. When there is any foreign matter larger than the thickness of the sheet into the mold, the device will shut down automatically and immediately and unconditionally. In addition, this machine installs two emergency stop switches.

PLC\ touch screen is Taiwan Taida,Electrical components is Omron or Schneider,Pneumatic Components isSoutheast pneumatic.

Parameter data | |

Processing Components Shape | Round shape tank |

Outer Tank Diameter | φ450mm—φ650mm |

Max. Effective Length | 3000mm |

Processing Material Thickness | 0.4-0.6m |

Max PN | 800KN |

Adjustment of Support beam | ≤30mm |

Adjustment of Slider | ≤50mm |

Slide stroke | 80mm |

Slider upper stop point | 130mm |

Stamping times | 60 time/min |

Power | 22KW |

Disposable Power | 80V±10% |

Input circuit | 380V |

The main motor circuit | 380V |

Control loop | 24V |

Frequency | 50HZ |

Operation labor | 2-4 people |

Work piece feed | Manual |

Weight | 13500kg |

Size (L*W*H) mm | 5000*2500*3200 |