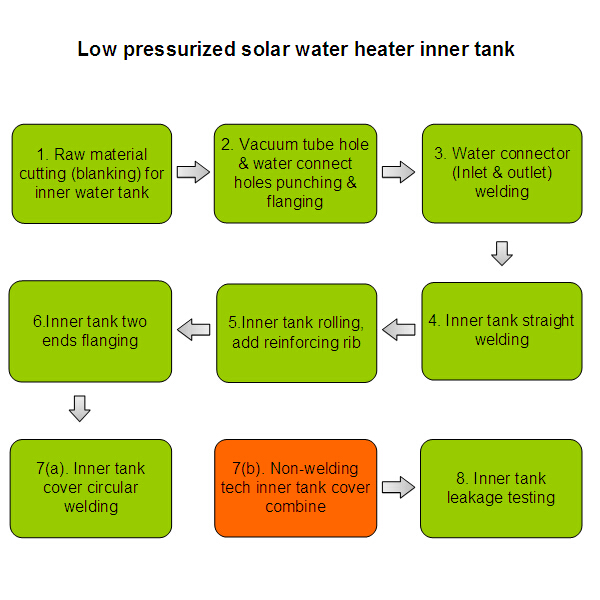

Solar water hater inner tank production line- Step 7. Non-welding tech inner tank cover combine

Application:

Non-welding technology inner tank covers combine

PLC automatic control systems, Automatic both ends of the occlusion compression. Whole the occlusion process can be completed in just 8 seconds, with beautiful shape, high level automation and work piece deformation. Electromagnetic clutch is installed, enable the device fast running and stop. Mounting bracket automatic landing function, allows the liner automatically into bite mold, install precision linear guide rail, ensure the concentricity of the whole flanging device. Bump disk \ bite mold \ bite reel. The pressure roller used in all Cr12 abrasives steel, vacuum Heat treatment, ensure the wear resistance of the mold.

Parameter data | |

Effective Length | 3000mm |

Mould diameter | Φ360 &Φ 380 (2 sets molds) |

Max. material thickness | 0.6mm |

Power | 4.0 kw *2 |

Voltage | 380v 501hz |

Air Pressure | 0.5Mpa—0.8 Mpa |

Operation Labor | 1person |

8 hours Max.Efficiency | 800pcs/8h |

Weight | 2900kg |

Size (L*W*H) mm | 5100*1200*1350 |

YOUTUBE LINK: https://youtu.be/QxDh2hxrsaA