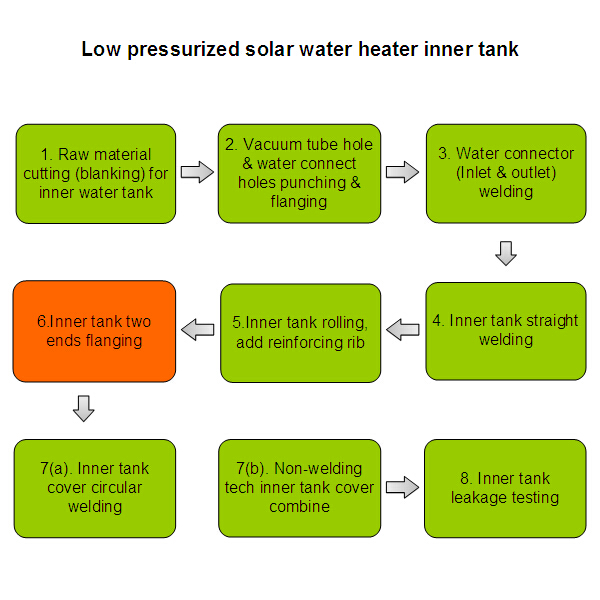

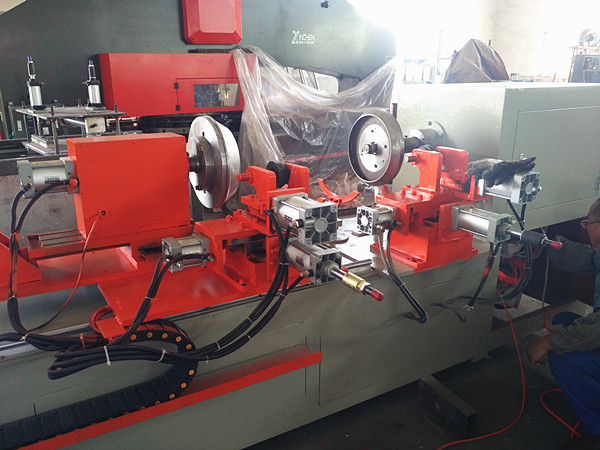

Solar water hater inner tank production line- Step 6.Inner tank two ends flanging (for inner tank cover non-welding tech OR vertical circular welding)

Application:

flanging for inner tank two ends, flanging for vertical welding and non-welding technology. (If inner tank cover adopt horizontal welding, then no need this machine)

PLC automatic control systems. Automatic fast flanging, two end processing at the same time, mounting bracket automatically. The lifting function enable the liner automatically into the flange mold, install the rack locking function allows flanging device firmly fixed on a point, not easy to slide. Install precision linear guide, ensure the concentricity of the whole flange device. The edge wheel adopt Gr12 high hardness mold steel, oil hardening heat treatment. Omron Electrical components, , Taiwan AirTAC cylinder Effective Length

Parameter data | |

Effective Length | 3000mm |

Mould diameter | Φ360 & Φ380 (2 sets mold) |

Max Flanging Thickness | 0.6mm |

Power | 2.0kw |

Voltage | 380v 50hz |

Air Pressure | 0.5Mpa—0.8 Mpa |

Operation Labor | 1people |

YOUTUBE LINK: https://youtu.be/bnekypkqcWY