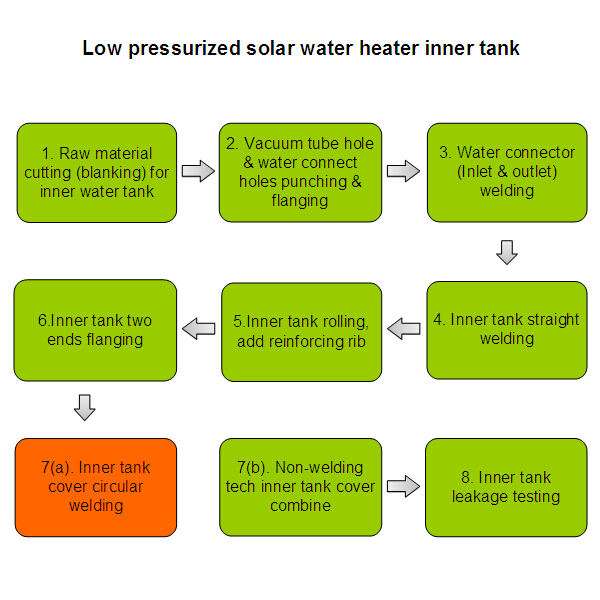

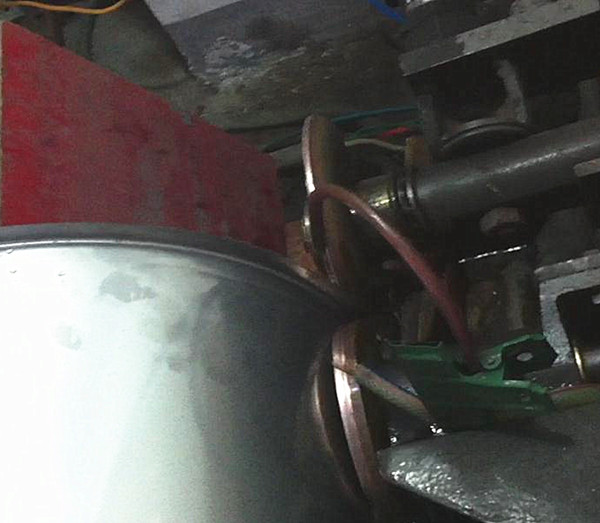

Solar water hater inner tank production line- Step 7. Inner tank cover circular welding

Application:

Inner tank cover circular seam welding

Using high power module and the microcomputer control system, the current stable, easy to adjust, the main transformer adpot import silicon steel sheet, all copper sand primary winding and cast copper braid is secondary, the entire process cold water protection. Welding copper wheel adopts high temperature resistant, wear resistant chromium zirconium copper, use gear motor,

Parameter data | |

Maximum welding thickness | |

DP-50 | 0.4mm+0.4mm |

DP-100 | 0.5mm+0.5mm |

Main transformer Rated capacity | 50KVA/100KVA |

Voltage | 380v 50HZ |

Secondary maximum short-circuit current | 20KA |

Duty cycle | 20% |

Air Pressure | 0.5Mpa—0.8 Mpa |

Operation Labor members | 1person |

8 hours Max. Efficiency | 80 PCS inner tank cover |

Weight | 450kg |

Floor space (L*W*H) mm | 2500*550*1700 |

YOUTUBE LINK: https://youtu.be/QxDh2hxrsaA