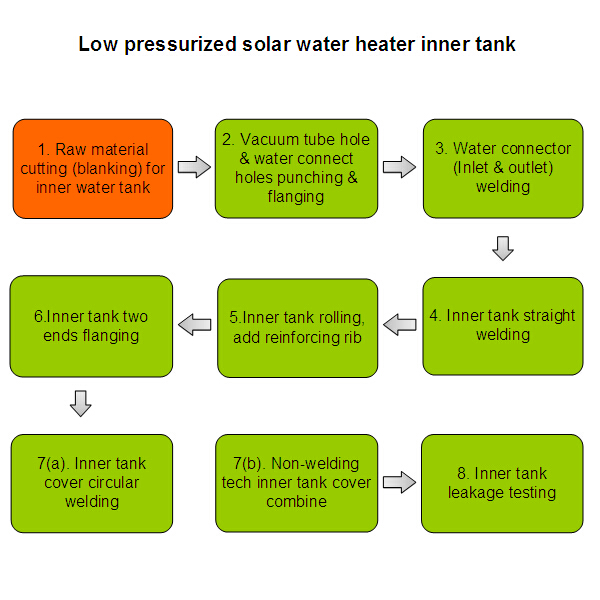

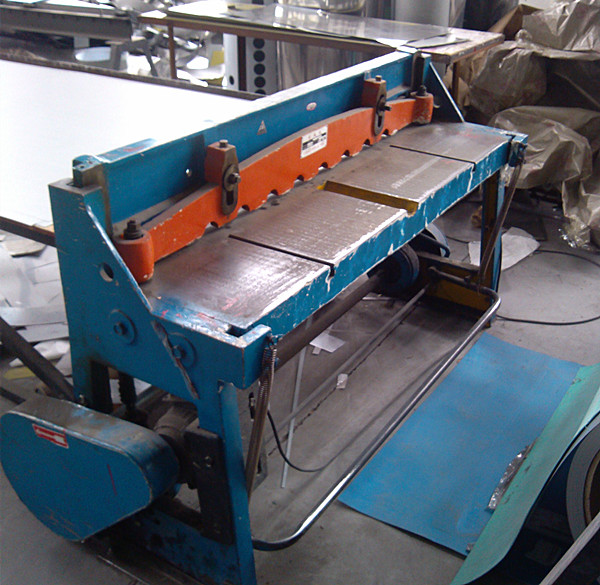

Solar water hater inner tank production line- Step 1. Raw material cutting (blanking) for inner water tank

Application:

Solar water heater inner & outer tank steel plate cutting (blanking)

Deployment Component:

1set Cutting Machine & 2 sets Steel coil putting stands

Adopt resistance turnkey clutch structure form and open gear. Shear automatic reset. Machine equipped with a keep-off device and foot bar folding device. Foot bar spring using sliding protection fixed. Machine body use cast iron. Cutting blade using all around cutting edges and 9GS stainless steel material, greatly improve the blade service life. Incision no burrs, high shearing quality.

Parameter data | |

Max Cutting Plate Width | 1300mm |

Max Cutting Plate Thickness | 0.5mm |

Operation Labor members | 3 person |

Steel coil putting stands Max Width | 1300mm |

Steel coil putting stands Max Load Weight | 7000 kg |

Voltage | 380v 50HZ |

Power | 1.5KW |

8 hours Max. Production | 1000 PCS Plate cutting |

Weight | 1300kg |

Production Line Dimension(Floor space L*W)mm | 4000mm*1600mm. Install two roll plates (8600*2400mm) Note: each roll plate add length 1200mm. Width is same. |

YOUTUBE LINK: https://youtu.be/QxDh2hxrsaA