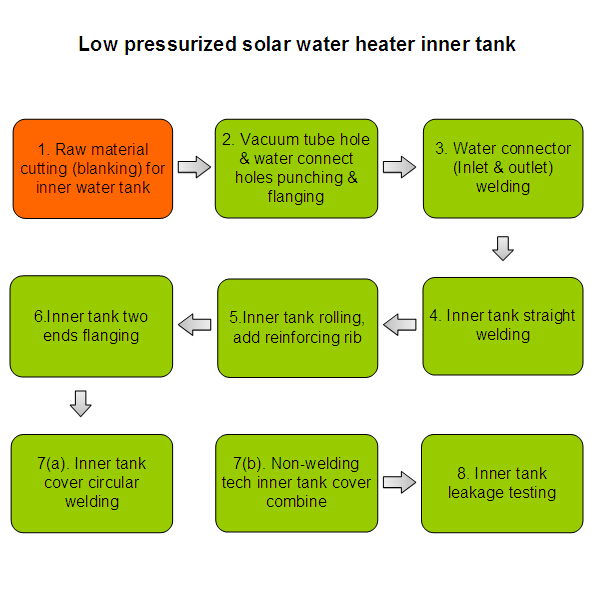

Solar water hater inner tank production line- Step 1. Raw material cutting (blanking) for inner water tank

Application:

solar water heater inner and outer tank steel plate auto Kaiping and Cutting

Deployment Component:

4 position coil stand with 3 pcs of coil holder, auto extend type.

tractor 1 set,

control box 1 set,

cutting and correcting system 1 set,

convey system 1 set,

air source cutting machine 1 set,

total 6 sets.

PLC computer control, discharge, leveling, lamination, Kaiping, the collection of paper, counting all run automatically, you only need to enter the shear size and number of sheets. The surface of the roller is plated hard chrome, traction roller 1 group, leveling roller 3 group, PN 400KN the hydraulic system provides power. Shears blade use W18Cr4V high-speed steel. Hydraulic system Power 5.5KW, leveling traction machine Power 4.0 frequency conversion motor

Parameter data | |

Length positioning accuracy | ±1.0mm |

Material Max. Width | 1300mm |

Max. Thickness | 0.5mm |

PN | 160KN |

Air Pressure | 0.5Mpa - 0.8 Mpa |

Tractor Power | 2.2 Inverter motor |

Hydraulic System Power | 4.0KW |

Power | 380V 50HZ |

Person | 2 people |

8 hours max production | 1000pcs sheet cutting |

Weight | 4200kg |

Floor space | Install two roll plates (8600*2400mm) Note: each roll plate add length 1200mm. Width is same. |

YOUTUBE LINK: https://youtu.be/QxDh2hxrsaA